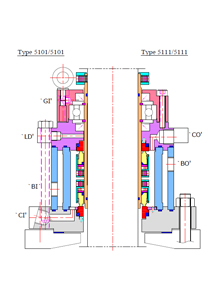

Unbalanced Double Back to Back Seal Super Style(For Top Entry Agitator) Agitator Seal 50 Series (5101/5101CR,5111/5111CR)

Face Materials

- Carbon

- Tungsten Carbide

- Silicon Carbide

- Ceramic

Secondary Seal

- 5101/5101 - ‘O’ Ring (Viton, EPR, Buna N, Aflas, Kalrez)

- 5111/5111-Wedge & Packing (PTFE GFT)

Metal Parts

- SS 316

- SS 304

- Alloy 20

- Monel Hastelloy-C

- Titanium

Application

- Chemicals and its Vapors

- Petrochemicals and its Vapors

- Light Hydrocarbons and its Vapors

Seal Features

- Multi Spring

- Double Seal Back to Back

- Unbalanced

- Independent of direction of rotation

- Operated with Pressurized Barrier Fluid

- Jacketed & heat Trapping Arrangement

Performance Limits

- Size – 1” to 8”

- Pressure – upto 8 Kg/cm2

- Temperature - -40°C to +200°C

- Barrier Fluid Pressure = Vessel Pressure + 1.5 Kg (Use Kalrez ‘O’ Ring for 250°C and above)

5101/5101 & 5111/5111 seal are Cartridge units for mixtures, agitators and reaction vessels. The heavy duty construction of the 50 series Provides long seal life and excellent repairability. The design incorporates bearing located very close to seal. The design specifically is engineered to accommodate the run-out conditions, upto 0.5 mm, large clearance between rotation shaft /Sleeve and mating ring permits higher deflection of the shaft.

For higher Temperature application, the Seal assembly has got jacketed chamber to circulate chilled water to bring down the temperature. Also normally chilled / plain water is passed through the cooling coil of Thermosyphon to bring down the temperature of compatible barrier fluid circulated in seal housing to maintain the continuous cooling. Bottom portion of seal Housing is also designed with heat trapping jacketed cooling to reduce the temperature around the bottom seal face.