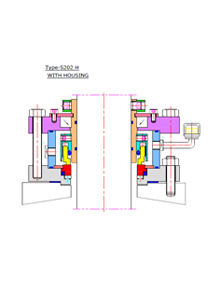

Wet Running Seal Super Style(For Top Entry Agitator, Vessels and mixers) Agitator Seal 50 Series (5202 H)

Face Materials

- Carbon

- Tungsten Carbide

- Silicon Carbide

- Ceramic

Secondary Seal

- 5202 H - ‘O’ Ring (Viton, EPR, Buna N, Aflas, Kalrez PTFE Cover Viton)

Metal Parts

- SS 316

- SS 304

- Alloy 20

- Monel Hastelloy-C

- Titanium

Application

- Food Products and its Vapors

- Pharmaceuticals Products and its Vapors

- Light Hydrocarbons and its Vapors

Seal Features

- Multi Spring

- Single Seal

- Reverse Balanced, outside mounted

- Independent of direction of rotation

Performance Limits

- Size – 1” to 8”

- Pressure – upto 8 Kg/cm2

- Temperature - Amb to +120°C

- Speed – 400 RPM

This is a single multi spring externally mounted, reverse balanced seal specifically designed for agitator & vessels.

The 5202 H seal design can be applied to all top entry agitator shafts, where the seal chamber is subjected only to gas or vapors.

The design specifically is engineered to accommodate the run-out conditions, upto 0.5 mm, large clearance between rotation shaft /Sleeve and mating ring permits higher deflection of the shaft.

These are used with non pressurized barrier fluid preferably clean soft water because of its good heat transfer qualities fluids like oil, hydrocarbon, Solvents etc can also be used as buffer fluid by considering the corrosion resistance of wetted parts & compatibility with main media to be sealed. These seals are supplied with cooling water Jacket, and Integral bearings which are closed to seals ensure optimum running and sealing conditions.