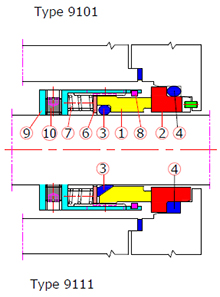

Multi Spring Mechanical Seal 90 Series (9101,9111,9101CR,9111CR)

Face Materials

- Carbon

- Tungsten Carbide

- Silicon Carbide

- Ceramic

- Glass Filled Teflon

- Silicon Filled Teflon

- Superalloy

Secondary Seal

- 9101–‘O’ Ring (Viton, EPR, Buna N, Aflas, Kalrez)

- 9111-Wedge & Packing (PTFE GFT)

Metal Parts

- SS 316

- SS 304

- Alloy 20

- Monel Hastelloy-C

- Titanium

Application

- Chemicals

- Petrochemicals

- Oil Refineries

- Food and Beverage

- Water and Waste Water

Seal Features

- Multi Spring

- Single Seal

- Unbalanced

- Inside Mounted

- Independent of direction of rotation

Performance Limits

- Size – 0.5” to 4”

- Pressure – upto 8 Kg/cm2

- Temperature - -40°C to +200°C (Use Kalrez ‘O’ Ring - 250°C)

Easy to install: Designed for compactness and narrow cross section, the seal slides into the smallest stuffing box for universal application.

Less Expensive: Designed parts are interchangeable. You can convert from an unbalanced seal to a balanced seal by changing only the seal ring.

Salient Features: The multi Spring provide uniform pressure all over seal faces and ensure the reliability under all conditions.

Long Life: Wedge or ‘O’ Ring allow lower spring loads and a cooler running seal. The ‘O’ ring Minimized sleeve fretting.

Immediate delivery: These type of seals are ready in stock