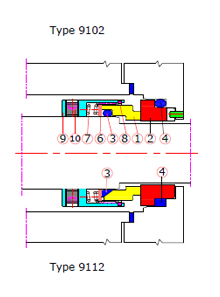

Multi Spring Mechanical Seal 90 Series (9102,9112,9102CR,9112CR)

Face Materials

- Carbon

- Tungsten Carbide

- Silicon Carbide

- Ceramic

- Glass Filled Teflon

- Silicon Filled Teflon

- Superalloy

Secondary Seal

- 9102–‘O’ Ring (Viton, EPR, Buna N, Aflas, Kalrez)

- 9112-Wedge & Packing (PTFE GFT)

Metal Parts

- SS 316

- SS 304

- Alloy 20

- Monel, Hastelloy-C

- Titanium

Application

- Chemicals

- Petrochemicals

- Oil Refineries

- Food and Beverage

- Water and Waste Water

Seal Features

- Multi Spring

- Single Seal

- Balanced

- Inside Mounted

- Independent direction of rotation

Performance Limits

- Size – 1” to 4”

- Pressure – upto 40Kg/cm2

- Temperature - -40°C to +200°C (Use Kalrez ‘O’ Ring for 250°C and above)

Easy to install Designed for compactness and narrow cross section, the seal slides into the smallest stuffing box for universal application.

Less Expensive Designed parts are interchangeable. You can convert from an unbalanced seal to a balanced seal by changing only the seal ring.

Salient Features The multi Spring provide uniform pressure all over seal faces and ensure the reliability under all conditions.

Long Life Wedge or ‘O’ Ring allow lower spring loads and a cooler running seal. The ‘O’ ring Minimized sleeve fretting.

Immediate delivery These type of seals are ready in stock